Abstract:

Textile sector plays a vital role on economy all over the world specially Bangladesh, China, India and some other developing country. Although clothing is one of our basic needs but it spreads also at Hi-Technical sector including Nano-technology. Not only general textile but also all technical textile processing related to wet processing specially for coloring of textile materials. It consumes an unbelievable amount of water in each and every steps of processing. The first and foremost aim of study in this field to reduce the use of water in textile processing. As a result important water quality parameters like pH, turbidity, TSS, BOD, COD and presence of metals remains in tolerable limit.

Background and Significance:

As I am from Bangladesh, I hope it will be easy to explain the Background and Significance to study on this topic from Bangladesh perspective. Bangladesh is a third world developing country. It is totally based on Textile Sector specially RMG (Ready Made Garments) for its economic development. Statistics shows that- about 80% foreign currencies comes each years from this sector. Although we draw a huge amount of foreign currencies from this sector, but it is my painful duty to inform you that- we have already polluted our environment especially by the effluent discharge from the dyeing machineries. As a result important water quality parameters of our industrial are seriously injured. Our most important rivers like Turag & Burigonga has already polluted seriously due to direct discharge of Effluent generated by Textile Industry. Although some factory establish ETP (Effluent Treatment Plant) but they did not run regularly due to its excessive costing. For this reasons I wish to develop to an alternative method of coloring of textile materials according to the theory of light. That’s reduced environmental pollution and save cost of wet processing.

Research Method;

Optical physics may help me to develop an alternative method of coloring of textile materials. Newton showed many years ago using a prism that white light is made up of contributions from all of the visible wavelengths. Light is a narrow range of electromagnetic energy, to which the human eye is sensitive.

I wish to develop a process of producing colors by addition and subtractions of textile materials. When light exposure on the materials some rays are absorbed and some are reflected. The reflected ray’s human eyes can identify as color which are in human visible range (approximately 380nm to 780nm).

Now let see how materials modify colors:

Case-1: Amount of light reflection/absorption: When individual ray incident on a surface than it may be reflected from a surface or absorbed by surface or transmitted through the surface. The amount of absorption and reflection is often dependent on the wavelength. Reflected light from an object, perceived by the human eye, is what gives an object its color.

Case-2: Amount of light Transition: Light can be transmitted, or passed through, an object in varying degrees. The amount of transmission can also be dependent on the wavelength. Certain wavelengths are transmitted and others are absorbed. This type of object appears translucent, and colored, such as a colored glass or plastic.

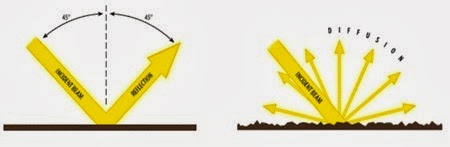

Case-3: Amount of light reflection angle with respect to incident: In major case of Opaque surface light reflected all major rays in various angles which depend up on surface quality. So we can say surface quality will affect the way in which the light is reflected. Smooth surfaces (glossy) reflect light in specular reflection manner. On the other hand the grainy surface reflects incident light at multiple angles in diffuse reflection manner. It may show different color of objects that’s perceived by the human eye.

Case-4: Absorbing & reflecting light simultaneously: All colors in objects result from selective absorption and reflection of light at various wavelengths. It may show different color of objects that’s perceived by the human eye.

Case-5: Absence or presence of some weaves length: An object will appear its “usual” color under white light because all wavelengths are present to be reflected but when the same object illustrated under a single light than it may show different color that’s perceived by the human eye.

Application on textile materials:

Just have to change physical properties of fiber or fabric as well as surface properties of material by mechanical application in a prescribe manner as particular amount of light can be reflect/absorb (Case-1) from the fiber surface or particular amount of light can be transmit (Case-2) through the fiber or particular amount of light can be in reflate in particular angle (Case-3) or particular amount of light can be reflect & absorb simultaneously (Case-4) or using of natural color that has already exists of fiber (Case-5)

Potential Benefits:

Background and Significance:

As I am from Bangladesh, I hope it will be easy to explain the Background and Significance to study on this topic from Bangladesh perspective. Bangladesh is a third world developing country. It is totally based on Textile Sector specially RMG (Ready Made Garments) for its economic development. Statistics shows that- about 80% foreign currencies comes each years from this sector. Although we draw a huge amount of foreign currencies from this sector, but it is my painful duty to inform you that- we have already polluted our environment especially by the effluent discharge from the dyeing machineries. As a result important water quality parameters of our industrial are seriously injured. Our most important rivers like Turag & Burigonga has already polluted seriously due to direct discharge of Effluent generated by Textile Industry. Although some factory establish ETP (Effluent Treatment Plant) but they did not run regularly due to its excessive costing. For this reasons I wish to develop to an alternative method of coloring of textile materials according to the theory of light. That’s reduced environmental pollution and save cost of wet processing.

Research Method;

Optical physics may help me to develop an alternative method of coloring of textile materials. Newton showed many years ago using a prism that white light is made up of contributions from all of the visible wavelengths. Light is a narrow range of electromagnetic energy, to which the human eye is sensitive.

I wish to develop a process of producing colors by addition and subtractions of textile materials. When light exposure on the materials some rays are absorbed and some are reflected. The reflected ray’s human eyes can identify as color which are in human visible range (approximately 380nm to 780nm).

Now let see how materials modify colors:

|

| Fig-1: Perceive color due to reflected & absorbed. |

|

| Fig-2: Color change due to light Transition |

|

| Fig-3: Color change due to different angle of reflation |

|

| Fig-4: Color change due to Absorption & reflection simultaneously |

|

| Fig-5: Color change due to Absence or presence of some weaves length [Apple under white light appears normal (red) but under green light appears dark or black] |

Application on textile materials:

Just have to change physical properties of fiber or fabric as well as surface properties of material by mechanical application in a prescribe manner as particular amount of light can be reflect/absorb (Case-1) from the fiber surface or particular amount of light can be transmit (Case-2) through the fiber or particular amount of light can be in reflate in particular angle (Case-3) or particular amount of light can be reflect & absorb simultaneously (Case-4) or using of natural color that has already exists of fiber (Case-5)

Potential Benefits:

- Reduce the water consumption in textile processing.

- Reduce the excessive use of chemicals.

- Benefits of Health and safety aspects as no chemicals usage.

- Practically no reactions are involved in their preparation.

- This process is unsophisticated and harmonized with nature.

- This might be cost effective due to no chemical processing and no ETP costing.

- It is possible to obtain a full range of colors using the theory of light.

- Basics of Light and Color: Texas Optoelectronic Solution

- Online magazine: Textile today

- Environmentally Friendly Techniques in Textiles By_Dr Arun Kanti Guha, Assistant Professor, Department of Textile Engineering, Southeast University.

No Responses to "Coloring of Textile Material Without Wet Processing"