ABSTRACT:

Of the last 3,422 years only, 268 years have been free from armed conflicts somewhere in the world. We can understand the effect of violence on the history of our mankind from the above statement. Defence forces have been used from ages back, to maintain law and order and also for acquiring more power by controlling the other nations. In all these wars, textile has played a vital role in providing protection to certain extent to the soldiers. From the skirmishing infantry to the modern day infantry we could see many developments in the field of providing protection in all forms to the soldiers. In olden days, man has been using natural fibers for providing protection on the war field and these were very heavy and bulkier. Gradually he started using high performance fibers in the textiles used for defence. But we should note that even though there are many developments in this field, it is very difficult for us to provide all the required functionality in a single garment, it has to be provided through layers of materials. And that’s what we are going to see in this report. I have started with the applications used in the past and have said about the developments of various materials in providing protection and have explained about the various functional criterion of the technical textile suitable for defence applications. Hope this will explain about what are defence textiles, their different functionality…

INTRODUCTION

To be prepared for war is one of the most effectual means of preserving peace.

-George Washington [1]

Defence forces on land, sea and air are reliant on technical textiles. It may be woven, knitted or non-woven. They may also be coated or laminated. These textiles offer invaluable properties for military forces. The following figure gives an idea about the properties provided by the technical textiles offered to the defence.

But we should understand that providing all the three properties in single clothing is very difficult and hence they are given by different layers in combat clothing system. Protection and defence are passive responses, i.e. they absorb the impending energy or impact for protecting the underlying structure.

HISTORY

Protective garments were used in defence from ages back. When we see through the history, we can understand the path travelled by the protective garments provided to the defence personnel, starting with the heavy metal gears used by the rulers of the past to today’s light weight armors. We will have a quick glance over the developments of the defence textiles in the following pages in two divisions.

INTRODUCTION

To be prepared for war is one of the most effectual means of preserving peace.

-George Washington [1]

Defence forces on land, sea and air are reliant on technical textiles. It may be woven, knitted or non-woven. They may also be coated or laminated. These textiles offer invaluable properties for military forces. The following figure gives an idea about the properties provided by the technical textiles offered to the defence.

|

| (FIG.1) |

HISTORY

Protective garments were used in defence from ages back. When we see through the history, we can understand the path travelled by the protective garments provided to the defence personnel, starting with the heavy metal gears used by the rulers of the past to today’s light weight armors. We will have a quick glance over the developments of the defence textiles in the following pages in two divisions.

|

| (FIG.2) |

We will see the developments in detail in the following pages. First we will see about the defence textiles that were used in the pre twentieth century, and then we will see about in the twentieth century.

PRE TWENTIETH CENTURY

PRE TWENTIETH CENTURY

- In the beginning, leather and mesh garments were used for protection against sword and spear attacks.

- There were some short comings in the clothing used before.

- Count Rumsferd and Benjamin Thompson brought application of textiles into Defence into the limelight.

- Count Rumsferd, an American Colonel published in 1792, “THE PHILOSPHICAL TRANSACTION” in which he has noted upon the trapped air’ part in providing thermal insulation. He was awarded Copley Medal for his work.

- Then military uniforms were improved in the medieval times and the improvements increased brightness, shine and the color of the uniform mainly for regimental identification and intimidation of the enemy.

- Mainly the colors used were danger colors and epaulettes were used for increasing the shoulder width of the fabric.

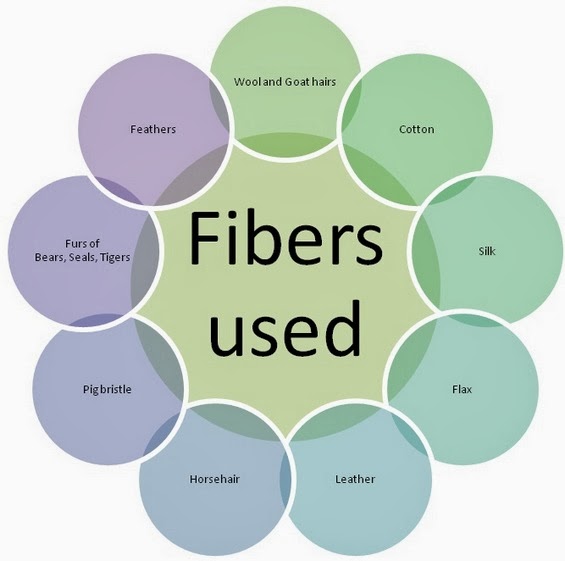

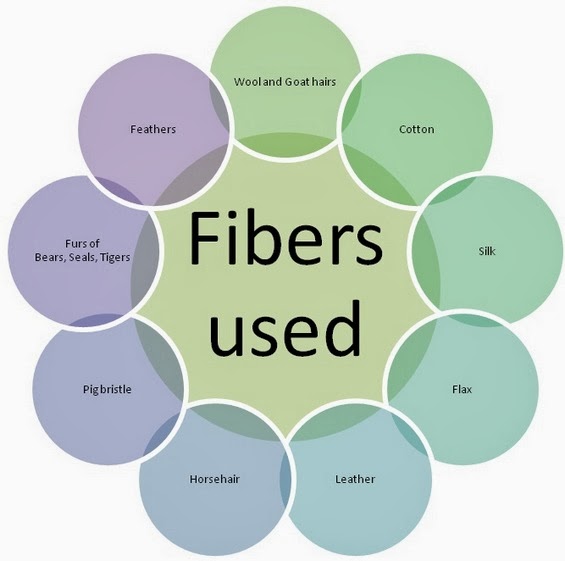

- The fiber types used were only natural and high performance fibers were not known at that time. The following figure throws light on the fibers used for the military uniforms.

(FIG.4)

TWENTIETH CENTURY

- Today’s military equipments are very advanced in all kinds. Sophisticated visual detection systems are used; hence it is very necessary hide troops and equipments by blending in with background.

- 1902 – Khaki uniforms came into existence. (Khaki means Dung in Persian and Dust in Urdu). The weave used was mainly wool worsted serge, i.e. a twill fabric.

- Natural environment has always been a threat to the military forces. A number of examples can be given for the defeat of a nation due to the natural environment.

- 1930s - UK war office[2] introduced combat clothing system which was cautious about providing the following three things

- Protection

- Comfort and

- Practicality

- 1939 – Worsted Serge battle dress was introduced under the specification E/1037 by Garment Development Section, Royal Dockyard, Woolwich, London [2].

- 1940 – Armored fighting vehicle crews were provided with one piece coverall black cotton denim.

- 1941 – Denison smock was introduced in this year. This is a lightweight windproof cotton gabardine fabric with rudimentary camouflage patterning for airborne paratroopers.

- 1943 – Layered combat clothing system came into existence which led woolen serge into obsoleteness [3].

- 1944 – Sand colored version of the one piece coverall was used for use in desert.

- 1945 – Nylon parachute canopies came into usage, Ventile cotton fabric were provided to the air crew. The special features of the Ventile cotton fabric was that they were water proof, water vapor permeable fabric and low twist Sea Island cotton and this was tightly woven.

- 1970s – Para – Aramid was introduced.

- Kevlar and Twaron continuous filaments which are woven into tight structure and assembled in multi – layers.

- This had high tenacity, good energy absorption, and high thermal stability.

- These garments can receive and neutralize a range of projectiles from low caliber hand guns (5.6 – 11.2 mm) to military bullets (5.56 – 7.72 mm)

- For protection against military bullets, the fabric will require ceramic tile reinforcements or other hard materials to blunt the tip of metal splinter pointed bullets.

- 1970 – 100% cotton satin drill fabric in olive green color was introduced.

- 1972 – DPM (Disruptively Patterned Material) with four color temperate woodland camouflage was introduced and this was the first ever printed material, which was introduced by UK war office.

- 1990 – Ultra High Molecular Weight Polyethylene with a commercial name Dyneema was introduced. This reduced the weight of the garment by about 15%. These are now used to produce cut resistant gloves, helmets and other protective garments.

All these developments were made keeping in mind that there is balance between garment weight, comfort and protection properties. This was possible because of the introduction of stronger and lighter fiber based reinforcements.

According to the technical textiles as for as ballistic protection is considered, we can see that it will be heavy, bulky and relatively inflexible. Nylon and polyester is used which possess no flame retardancy.

When we see the textile used for ballistic protection, it is also seen that apart from stopping bullets and bomb fragments, they provide high thermal insulation causing heat stress also. And when we go for air permeable fabrics, they are insect proof. Hence providing all the properties in a textile material is very difficult and needs a lot of research.

The properties said above are explained briefly in the following pages.

ENVIRONMENTAL PROTECTION

The military forces have to work in all parts of the globe, in a wide range of environmental conditions, like rain, snow, fog, wind, lightning, sunlight, dust, heat, cold, wet, high UV areas, and wind-chill. Defence standard 00-35 [5] defines the worldwide conditions in which men, women, equipments and weapon have to operate effectively. The highest priority in any environment is the protection of the individual.

THERMAL INSULATION

Defence personnel those who are working in cold/dry conditions like Arctic and Antarctic, and other mountainous regions of the world have to carry clothing, sleeping bags, personal equipments and these material require high levels of thermal insulation. Fibrous material offer resistance to heat transmission due to the air enclosed between and on the fiber surface. Normally an efficient insulator will have 10 – 20% of fiber and 80 – 90% air enclosed in between the surface. The fiber in fabric or other material whatever it is acts a large surface area medium to trap still air .

According to the technical textiles as for as ballistic protection is considered, we can see that it will be heavy, bulky and relatively inflexible. Nylon and polyester is used which possess no flame retardancy.

When we see the textile used for ballistic protection, it is also seen that apart from stopping bullets and bomb fragments, they provide high thermal insulation causing heat stress also. And when we go for air permeable fabrics, they are insect proof. Hence providing all the properties in a textile material is very difficult and needs a lot of research.

The properties said above are explained briefly in the following pages.

ENVIRONMENTAL PROTECTION

The military forces have to work in all parts of the globe, in a wide range of environmental conditions, like rain, snow, fog, wind, lightning, sunlight, dust, heat, cold, wet, high UV areas, and wind-chill. Defence standard 00-35 [5] defines the worldwide conditions in which men, women, equipments and weapon have to operate effectively. The highest priority in any environment is the protection of the individual.

THERMAL INSULATION

Defence personnel those who are working in cold/dry conditions like Arctic and Antarctic, and other mountainous regions of the world have to carry clothing, sleeping bags, personal equipments and these material require high levels of thermal insulation. Fibrous material offer resistance to heat transmission due to the air enclosed between and on the fiber surface. Normally an efficient insulator will have 10 – 20% of fiber and 80 – 90% air enclosed in between the surface. The fiber in fabric or other material whatever it is acts a large surface area medium to trap still air .

|

| Thermal insulation |

WATER VAPOR PERMEABILITY / WATER PROOFING

Water proof material allows free passage of water vapor. In extreme war operations, one can’t choose the climatic conditions or the intensity of their activities and if the above properties are not apt in the fabric, they may lead to injury or death due to hypo/hyperthermia. The following table will show us the effects of wearing impermeable clothing in different conditions.

Conditions

|

Activity

|

Consequences

|

Cold/ wet climate

|

Medium activity

|

Discomfort

|

Cold/ wet climate in sweat wetted clothing

|

High activity followed by low activity

|

Hypothermia

|

Hot moist climate and wearing protective clothing

|

High activity

|

Hyperthermia

|

CAMOUFLAGE CONCEALMENT AND DECEPTION

The word ‘camouflage’ is derived from French word ‘Camoufler’ meaning ‘to disguise’. The camouflage patterns were introduced by French for the first time during the World War I. but before that plain camouflages were introduced by India in 1850s, i.e. in the form Khaki uniforms. These camouflages should be effective in all the wavebands of detection used by the military forces, i.e. UV, near IR and far IR. The basic objective of the camouflage is that, the observation and detection should be as far as possible, and it should be a passive process.

Textile camouflages are in the form of flexible nets, garnishing, and clothing items.

FLAME REATRDENT HEAT PROTECTIVE TEXTILES

The civilian fires are mainly accidental but as far as the military fires are considered, they are deliberately planned events and out of all the textiles used in military are the first to ignite. Some of the flame retardant applications of textiles in defence are as follows,

Textile camouflages are in the form of flexible nets, garnishing, and clothing items.

FLAME REATRDENT HEAT PROTECTIVE TEXTILES

The civilian fires are mainly accidental but as far as the military fires are considered, they are deliberately planned events and out of all the textiles used in military are the first to ignite. Some of the flame retardant applications of textiles in defence are as follows,

|

One should understand the threats actually brought onto the defence people due to the flame and heat caused in the environment. The following figure depicts the military flame and heat threat.

BALLISTIC PROTECTIVE MATERIALS

The purpose of the ballistic protective materials is not to just stop the speeding bullets but to protect the individual from fragmenting devices as well, i.e. form grenades, mortars, artillery shells, and improvised explosive devices. We should note that the injury caused to the civilians is mainly due to two factors,

BALLISTIC PROTECTIVE MATERIALS

The purpose of the ballistic protective materials is not to just stop the speeding bullets but to protect the individual from fragmenting devices as well, i.e. form grenades, mortars, artillery shells, and improvised explosive devices. We should note that the injury caused to the civilians is mainly due to two factors,

- High velocity bullets from rifles, machine guns which are mainly shot from a long range.

- Low velocity bullets from hand guns which are shot from close range.

But when it comes to military personnel, they are three main factors.

|

The technical people who are working on the protective textiles should understand that the velocities of the bullets possess more weightage than the kinetic energy, bullet shape and the composition of the bullet [7].

Another point in this is that, the understanding of the raised levels of protection by the use of the armor and helmet today from the day when there was no armor at all.

This experimentation is done on troops standing in open ground threatened by a mortar bomb.

FIBERS USED IN BALLISTIC PROTECTION

Earlier, woven silk fabrics were used for ballistic protection. More recently high modulus aliphatic nylon 6.6 with high degree of crystalline and low elongation was developed and widely used in body armor and as textile reinforcement in composite helmets.

KEVLAR

Developed by DuPont, this is widely used in the modern generation of light weight body armors. It consists of long molecular chains produced from poly-phenylene terephthalamide. The chains are highly oriented with strong inter chain bonding that results in unique combination of properties, which include high tensile strength at low weight, low elongation at break, high modulus, low electrical conductivity, high chemical resistance, low thermal shrinkage, high toughness, excellent dimensional stability, high cut resistance and flame resistance. It does not melt and is unaffected by moisture. It is five times stronger than steel on an equal weight basis.

TWARON

This is another pararamid fiber. The yarn uses 1000 or more finely spun a single filament that acts as an energy sponge, absorbing a bullet’s impact and quickly dissipating its energy through engaged and adjacent fibers. Because more filaments are used, the impact is dispersed more quickly.

SPECTRA

This fiber is an ultra high strength polyethylene fiber. Ultrahigh molecular weight polyethylene is dissolved in a solvent and fibers are produced through gel spinning process. These fibers are 10 times stronger than steel, more durable than polyester and has a specific strength 40% greater than aramid fibers.

DSM DYNEEMA

It has extremely high strength to weight ratio and is light enough to float on water. It has high energy absorption characteristics and dissipates shock waves faster.

BIOLOGICAL AND CHEMICAL PROTECTION

We should understand that toxic agents cause emotional and lethally horrific effect. These are insidious mass destruction weapons. There are primary and essential devices for protection. There is ori-nasal and full face respirators and these filters out and de-activate toxic species. These respirators contain activated carbon on a textile substrate, which absorbs the agent vapor. The activated carbon are provided in any of the following three forms,

Another point in this is that, the understanding of the raised levels of protection by the use of the armor and helmet today from the day when there was no armor at all.

This experimentation is done on troops standing in open ground threatened by a mortar bomb.

FIBERS USED IN BALLISTIC PROTECTION

Earlier, woven silk fabrics were used for ballistic protection. More recently high modulus aliphatic nylon 6.6 with high degree of crystalline and low elongation was developed and widely used in body armor and as textile reinforcement in composite helmets.

KEVLAR

Developed by DuPont, this is widely used in the modern generation of light weight body armors. It consists of long molecular chains produced from poly-phenylene terephthalamide. The chains are highly oriented with strong inter chain bonding that results in unique combination of properties, which include high tensile strength at low weight, low elongation at break, high modulus, low electrical conductivity, high chemical resistance, low thermal shrinkage, high toughness, excellent dimensional stability, high cut resistance and flame resistance. It does not melt and is unaffected by moisture. It is five times stronger than steel on an equal weight basis.

TWARON

This is another pararamid fiber. The yarn uses 1000 or more finely spun a single filament that acts as an energy sponge, absorbing a bullet’s impact and quickly dissipating its energy through engaged and adjacent fibers. Because more filaments are used, the impact is dispersed more quickly.

SPECTRA

This fiber is an ultra high strength polyethylene fiber. Ultrahigh molecular weight polyethylene is dissolved in a solvent and fibers are produced through gel spinning process. These fibers are 10 times stronger than steel, more durable than polyester and has a specific strength 40% greater than aramid fibers.

DSM DYNEEMA

It has extremely high strength to weight ratio and is light enough to float on water. It has high energy absorption characteristics and dissipates shock waves faster.

BIOLOGICAL AND CHEMICAL PROTECTION

We should understand that toxic agents cause emotional and lethally horrific effect. These are insidious mass destruction weapons. There are primary and essential devices for protection. There is ori-nasal and full face respirators and these filters out and de-activate toxic species. These respirators contain activated carbon on a textile substrate, which absorbs the agent vapor. The activated carbon are provided in any of the following three forms,

- Finely divided powder coating

- Small beads

- Fiber fabric form.

The activated carbon possesses pore structure which provides a high surface area facilitating absorption of a wide spectrum of toxic gases. There are two methods of removal of toxic gases [8].

Today, the activated charcoal is on air permeable non woven supported on a foam backed textile or a laminate consisting of two textile fabrics sandwiching a charcoal layer.

FUNCTION SPECIFIC STUDY

FLAME RESISTANCE GARMENTS

Protection for the individuals has always been quite important in any workplace. Today, flame resistant suits have become quite indispensable in several kinds of workplace environments. One of the important safety measures is to protect the individuals with good quality flame resistant suits. Flame resistant suits are full-sleeved coveralls, though you can even find the same kind of fire protection with bib overalls. The coveralls are considered to be better because they cover more of the body and hence provide better safety from accidental flames. These suits are generally made with Ultra Soft material which is a blend of 88% natural fiber cotton with 12% of synthetic nylon material.

This blend is considered to be a safety standard in flame resistance. It can keep away high resistance flames, and is also used in the military for the same kind of protection. An advantage is that this material looks quite trendy from the outside, since it uses cotton. So, flame resistant suits can be considered a blend of safety and stud fashion.

Inside the Ultra Soft outer layer, inside, a lining of Modacrylic is provided, which is another high degree flame resistant material. The two linings are kept together with Nomex, which also has fire retarding properties. Most of these flame resistant suits are fastened with brass zippers attached to the front of the suits with Nomex material. The various pockets might also have zippers of brass. So, you can see, each and every component of the flame resistant suits is quite ready to combat any accidental breakthrough of fire.

IMPACT PROTECTION TEXTILES

For years the manufacturers of high-performance apparel have struggled to develop the systems that protect against high energy impacts without sacrificing flexibility, breathability or ease of use. APS is an intelligent fabric that consists of 3-D spacer textile treated with specially formulated, response silicon coating. It remains soft and flexible under normal conditions but when stressed under high impact force; the material instantly becomes rigid and then immediately returns to a flexible state.

This innovative material offers the unique combination of benefits that is particularly suited for use in high performance protective apparel and equipment. These benefits include:

Today, the activated charcoal is on air permeable non woven supported on a foam backed textile or a laminate consisting of two textile fabrics sandwiching a charcoal layer.

FUNCTION SPECIFIC STUDY

FLAME RESISTANCE GARMENTS

Protection for the individuals has always been quite important in any workplace. Today, flame resistant suits have become quite indispensable in several kinds of workplace environments. One of the important safety measures is to protect the individuals with good quality flame resistant suits. Flame resistant suits are full-sleeved coveralls, though you can even find the same kind of fire protection with bib overalls. The coveralls are considered to be better because they cover more of the body and hence provide better safety from accidental flames. These suits are generally made with Ultra Soft material which is a blend of 88% natural fiber cotton with 12% of synthetic nylon material.

This blend is considered to be a safety standard in flame resistance. It can keep away high resistance flames, and is also used in the military for the same kind of protection. An advantage is that this material looks quite trendy from the outside, since it uses cotton. So, flame resistant suits can be considered a blend of safety and stud fashion.

Inside the Ultra Soft outer layer, inside, a lining of Modacrylic is provided, which is another high degree flame resistant material. The two linings are kept together with Nomex, which also has fire retarding properties. Most of these flame resistant suits are fastened with brass zippers attached to the front of the suits with Nomex material. The various pockets might also have zippers of brass. So, you can see, each and every component of the flame resistant suits is quite ready to combat any accidental breakthrough of fire.

IMPACT PROTECTION TEXTILES

For years the manufacturers of high-performance apparel have struggled to develop the systems that protect against high energy impacts without sacrificing flexibility, breathability or ease of use. APS is an intelligent fabric that consists of 3-D spacer textile treated with specially formulated, response silicon coating. It remains soft and flexible under normal conditions but when stressed under high impact force; the material instantly becomes rigid and then immediately returns to a flexible state.

This innovative material offers the unique combination of benefits that is particularly suited for use in high performance protective apparel and equipment. These benefits include:

- Fully integrated active safety that can be stitched directly into the garments

- Material customization and versatility that allow many creative design possibilities

- Breathable, flexible and lightweight construction for outstanding comfort and freedom of movement

- Washable for easy care and maintenance

DECONTAMINATION TECHNOLOGY

In one of the existing technology it is based on micro-porous membranes. The new micro porous membranes have been developed at the U.S. Army Natick Soldier Center using the process of electro-spinning. Scientists at the Naval Research Laboratory’s Center for Bio/Molecular Science and Engineering (CBMSE) have developed a new cost-effective, self-decontaminating ultra thin materials coating that actively destroys pesticides and related chemical agents on contact. The coating neutralizes toxins instantly leaving no hazardous residue, which makes it ideal for use in protective clothing for military personnel and civilians. The coating can also be applied to materials used in filters for water purification, and in wipes for chemical spill clean-ups. Unlike composite fabrics, where rubber or synthetic alternatives are sandwiched between layers, the NRL approach coats each individual thread before it’s woven so that the fabric is treated throughout. This is significant in several ways. It will mean light, comfortable protective clothing that will draw off body moisture when used in warmer climates. And, because the coating is active throughout, it provides better protection against permeation and ensures the integrity of seamed areas on pieced fabric.

In another development the U.S. Army Edgewood Chemical Biological Center (ECBC) developed a patented technology to neutralize organo-phosphorus chemical agents and pesticides. This enzyme-based technology simplifies and improves the process of decontaminating a class of highly toxic chemicals, including nerve agents. Other decontamination methods use corrosive chemicals that are more costly, less efficient, and generate a substantial amount of residue waste.

ECBC partnered with Genencor International, Inc. to manufacture this licensed enzymatic decontamination technology, which is trademarked and known as DEFENZ™. DEFENZ™ is now on the market and available to companies that produce and sell fire fighting foams and sprays. All-Clear™, developed by Kidde Fire Fighting Inc, is the first commercially available decontaminant that incorporates these enzymes developed by ECBC. All-Clear™ neutralizes agents without harmful effects on sensitive apparatuses like landing gear and brake assemblies, and has proved to be non-corrosive in Boeing Series Corrosion testing.

In one of the existing technology it is based on micro-porous membranes. The new micro porous membranes have been developed at the U.S. Army Natick Soldier Center using the process of electro-spinning. Scientists at the Naval Research Laboratory’s Center for Bio/Molecular Science and Engineering (CBMSE) have developed a new cost-effective, self-decontaminating ultra thin materials coating that actively destroys pesticides and related chemical agents on contact. The coating neutralizes toxins instantly leaving no hazardous residue, which makes it ideal for use in protective clothing for military personnel and civilians. The coating can also be applied to materials used in filters for water purification, and in wipes for chemical spill clean-ups. Unlike composite fabrics, where rubber or synthetic alternatives are sandwiched between layers, the NRL approach coats each individual thread before it’s woven so that the fabric is treated throughout. This is significant in several ways. It will mean light, comfortable protective clothing that will draw off body moisture when used in warmer climates. And, because the coating is active throughout, it provides better protection against permeation and ensures the integrity of seamed areas on pieced fabric.

In another development the U.S. Army Edgewood Chemical Biological Center (ECBC) developed a patented technology to neutralize organo-phosphorus chemical agents and pesticides. This enzyme-based technology simplifies and improves the process of decontaminating a class of highly toxic chemicals, including nerve agents. Other decontamination methods use corrosive chemicals that are more costly, less efficient, and generate a substantial amount of residue waste.

ECBC partnered with Genencor International, Inc. to manufacture this licensed enzymatic decontamination technology, which is trademarked and known as DEFENZ™. DEFENZ™ is now on the market and available to companies that produce and sell fire fighting foams and sprays. All-Clear™, developed by Kidde Fire Fighting Inc, is the first commercially available decontaminant that incorporates these enzymes developed by ECBC. All-Clear™ neutralizes agents without harmful effects on sensitive apparatuses like landing gear and brake assemblies, and has proved to be non-corrosive in Boeing Series Corrosion testing.

MODULAR COMBAT CLOTHING SYSTEM

The main objectives of the modular combat clothing system are

|

|

1. To increase on field performance of the soldier

- Less weight and improved pack ability

- Environmentally versatile over a wide range of climatic conditions

- Increased protection and wear comfort

2. To optimize cost effectiveness

- Reduction in the number of different articles and materials of clothing

- Outstanding functionality and longer life cycle

- Easier adaptation to new developments

CONCLUSION

The main military nations have research programs geared towards future combat and protective clothing as integrated systems. The programs tend to be led by military threats or capability gaps doctrine, rather than exploitation of new technologies for the sake of it. The systems approach involves all the major stakeholders, including, strategic planners, users, equipment capability managers, operational analyzers, R&D scientists, producers, contracts staff etc. The general aims of future systems are:

The main military nations have research programs geared towards future combat and protective clothing as integrated systems. The programs tend to be led by military threats or capability gaps doctrine, rather than exploitation of new technologies for the sake of it. The systems approach involves all the major stakeholders, including, strategic planners, users, equipment capability managers, operational analyzers, R&D scientists, producers, contracts staff etc. The general aims of future systems are:

- Improve protection against natural and battlefield threats

- Maintain thermo-physiological comfort or survival in extreme conditions

- Improve compatibility between and within different clothing components

- Reduce weight and bulk of materials

- Integrate functionality so that fewer layers provide multi layer protection

- Reduce life cycle costs by making systems more effective, durable, and recyclable and by buying few components in the system

REFERENCES

- George Washington, Speech to American Congress, 1790

- MG Burns, British combat dress since 1945, Arms and Armor press, Clasell, London, pp 6, 7, 15.

- M.Chapell, The British soldier in the twentieth century, Part 5 Battledress 1939-1960, Wessex Military Publishing, Hathersleigh Devon 1987 pp 8 – 16

- GT Holmes, 8th Commonwealth Conference on clothing and General Stores, Department National Defence, Canada 1965

- Defence standard 00-35, Issue 2 Environmental hand book for defence materials Chapter 1-01, Table 2 MOD, Directorate of Standards 6, March 1996, P 5

- C Cooper, Textile as protection against Extreme winter weather’ textiles 1979, 8 (3) 72-83

- L Tobin Military and Civilian Protective clothing, MOD, DCTA lecture given to RMCS wound ballistic course. Jan 1994

- Specification UK/SC/3346G, cloth, Bonded, Multi Fiber Anti Gas, MOD, DCTA, QPS, DIDCOT, OXON, Sep 1982

- Hand Book of Technical Textiles by Sabit Adanur

- www.wikipedia.com

- www.technicaltextile.net

No Responses to "An Overview of Defence Textile"