Sound Absorption Performance of Natural Fibers and Their Composites

Rahamat Ullah Joy

B.sc in Textile Engineering

Daffodil International University

Email: rahamat.tex@gamil.com

Abstract

This research aimed to study the sound absorption properties of natural fibers and their reinforced composites. Sound absorption coefficients of three types of natural fibers, i.e., ramie, flax and jute fibers and their composites were measured by the two-microphone transfer function technique in the impedance tube. The results were compared with synthetic fibers and their composites. It was found that both natural fibers and their composites had superior capability of noise reduction. The multi-scale and hollow lumen structures of natural fibers contributed to the high sound absorption performance. Moreover, the sound absorption properties of these natural fibers were also calculated by the Delany-Bazley and Garai-Pompoli models. They showed good agreement with the experimental data. It was concluded that multi-functional composite materials can be made by natural fibers so that both the mechanical and acoustical functions can be achieved.Eco-friendly green/biocomposites were fabricated from chopped hemp fiber and cellulose ester biodegradable plastic through two process engineering approaches: powder impregnation through compression molding (process I) and extrusion followed by injection molding (process II). Cellulose ester, e.g. cellulose acetate (CA) plasticized with 30 wt% citrate plasticizer (CAP) was used as the matrix polymer for biocomposite fabrication. Intimate mixing due to shear forces experienced in process II produced superior strength biocomposites over their counterparts made using process I. Biocomposite fabricated through process II containing 30 wt% hemp natural fiber showed an improvement of storage modulus by 150% over the virgin matrix polymer. The coefficient of thermal expansion of the said biocomposite decreased from the CAP polymer by 60% whereas the heat deflection temperature improved by 30% versus the virgin bioplastic, indicating superior thermal behavior of the biocomposite. Plasticized cellulose acetate is proved to be much better matrix than non-polar polypropylene (PP) for hemp fiber (HF) reinforcements because of the better interaction of polar cellulose ester with the polar natural fiber. Fabricated through process II and with same content of hemp (30 wt%) the CAP-HF based biocomposite exhibited flexural strength of 78 MPa and modulus of elasticity of 5.6 GPa as contrast to 55 MPa and 3.7 GPa for the corresponding PP-HF based composite. The experimental findings of tensile modulus of the biocomposites are compared with the theoretical modulus using the rule of mixture. The fiber-matrix adhesion is evaluated through environmental scanning electron microscopy studies.

Keywords: A. Polymer-matrix composites (PMCs); B. Thermomechanical; Natural fibers

|

Fig. 1. Structure of cellulose esters (cellulosic plastics): R=H (cellulose), acetyl (cellulose acetate), acetyl and propionyl (cellulose acetate propionate), or butyryl (cellulose acetate butyrate). |

|

| Fig. 2. ESEM micrograph of raw hemp fiber (100 μm scale bar, 600×). |

|

| Fig. 5. Flexural properties of CAP biocomposites of process II: A=CAP (0 wt% hemp), B=15 wt% hemp, C=30 wt% hemp content. |

|

| Fig. 6. Stress–strain plot of: A=virgin cellulose acetate plastics (CAP) and B=CAP biocomposites (30 wt% hemp). |

|

| Fig. 7. Comparison between tensile modulus of rule of mixture (ROM), modified ROM, and experimental tensile modulus with density of raw hemp (ρ)=1.29 g/cc, tensile modulus of hemp fiber. |

|

| Fig. 8. Heat deflection temperature (HDT) data comparison of A=CAP (0 wt% hemp), B=15 wt% hemp, C=30 wt% hemp content. |

|

| Fig. 9. Coefficient of thermal expansion (CTE) data comparison of A=virgin cellulose acetate plastics (CAP) and B=CAP biocomposites (30 wt% hemp). |

|

| Fig. 10. Flexural properties comparison of: A=CAP, B=CAP-30 wt% hemp composites, C=PP, D=PP-30 wt% hemp composites. |

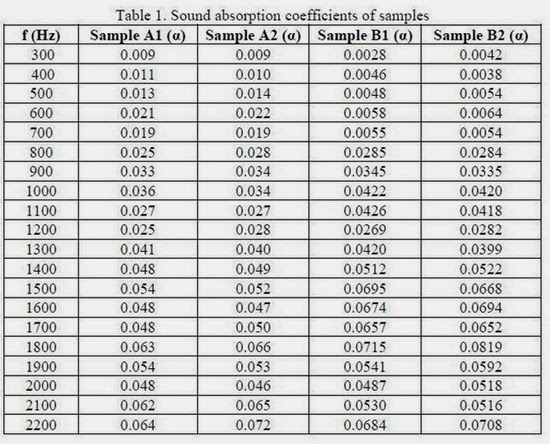

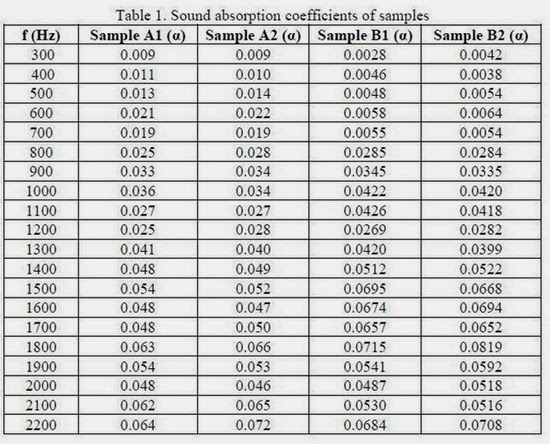

In this Investigation, the influence of two kind of polymers (Urea-formaldehyde and Polypropylene) mixed with natural fibre (Kenaf) were studied for their sound absorption coefficients.Four samples were made; Samples A1 and A2 are made of Kenaf core fibre with adhesive of highemission Urea-formaldehyde resin (HN 100) with 51.6 % solid content. The fabrication of the particle board was done using a hot press for 6 minutes under the pressure of 40 Ton at 1800C for different fibre lengths 1 mm (Sample A1) and 0.6 mm (Sample A2) with weight fraction of 80%. Sample B1 and B2 are made of Kenaf core fibre with polypropylene matrix materials with coupling agent of polyvinyl alcohol. The fabrication of the sample was done using hot press for 30 minutes under the pressure of 1000 Psi at 1800C for different lengths of 1 mm (Sample B1) and 0.6 mm (Sample B2) with weight fraction of 20%. The sound absorption coefficients of samples were measured according to American society for Testing Materials (ASTM E1050 10) two microphone method. It is evident that type of polymer influences the sound absorption coefficients.It is clearly undeniable that the development of global industry, science and technology has considerably raised the quality of life. However, this process also simultaneously leads to numerous problems, especially environmental issues and human’s health. Every day, billions of people throughout the world have to face with many unpleasant effects such as: air pollution, water pollution and so forth. Beside these, noise pollution is also seriously influencing human’s life as well,particularly the lives of city’s dwellers. Noise pollution stems from a variety of sources. This may be the results of industrial processes or from the daily life’s activities. Sound absorption constitutes one of the major requirements for human comfort today. Sound insulation requirements in automobiles, manufacturing environments, and equipment, generating higher sound pressure drive the need to develop more efficient and economical ways of producing sound absorption materials.

Industrial applications of sound insulation, generally includes the use of materials such as glass wool, foam, mineral fibres and their composites. In the recent years, a number of studies have been carried out to develop new materials and technologies improving the sound absorption properties Since the noise problem has become much more complex and serious; the demands for a better environment and more diversified life styles increased. Therefore, the thin, lightweight, and low-cost materials that will absorb sound waves in wider frequency regions are strongly desired. Recently, polymer has been extensively applied for absorption of sound and reduction of noise, whose attractive characteristics include its excellent viscoelasticity, relatively simple processing, and commercial availability.A porous laminated composite material manufactured by lamination, preheating and moulding of premix, exhibits a very high sound absorption property in the frequency range 500–2000 Hz .Two-stage compression moulding of recycled polyolefin-based packaging wastes along with plastic-coated aluminium foils, expanded polystyrene and coir pith, offers sound absorption properties comparable to glass wool [4]. Combinations of non-woven fabric and Para-amid paper were studied and a sound absorption performance at frequencies higher than 2000 Hz was found to be better than that of glass wool [5]. Use of recycled rubber particles with perforated, polymer-material results comparable sound absorption properties. The sound absorption of the composite material is dominated by recycled rubber when the rubber particle size is small, whereas the property is influenced by polymer porous material when the rubber particle size is larger. A composite structure with a combination of perforated panel, rubber particle, porous material, polyurethane (PU) foam and glass wool were found to demonstrate significant sound attenuation [6]. Usually, wasted rubber particles demonstrate lower sound absorption at higher frequencies. This is altered by matching polypropylene and polystyrene particles, resulting a novel composite material with higher sound absorption for a wider frequency range .

Sound Absorption Composite Materials

Natural fibres are low-cost, lightweight and environmental friendly compared to glass fibre andmineral based synthetic materials. Moreover, natural fibres are sustainable, i.e. a resource produce for the needs of present without affecting the future needs.In addition, these natural materials are bio-degradable, nonabrasive, abundance and having less health and safety risk while handling and processing [9]. D’alessandro and Pispola [10] measure sound absorbing panels made of Kenaf and blankets of recycled polyester (PET) fibres. Both samples were tested in reverberation chamber, acoustic properties of both samples are good at frequency rangebetween 1000 Hz to 5000Hz with the average of 0.8. Yang et al. [11] utilized rice straw to become insulation boards to overcome lacking of solid woods in wood-industry. The rice straw was mixed with commercial binder to have certain shape and strength. The absorption coefficient is found to be on the average 0.5 between 1000 Hz to 8000 Hz. Sound absorption characteristic values of rock wool were measured and found to be similar to glass fibre [12].From the view of environmental protection, natural bamboo fibres were used for sound absorbing purposes. Impedance tube measurement of the bamboo fibre samples, reveal similar properties to that of glass wool. [13]. Composite boards of random cut rice straws and wood particles, were found to demonstrate higher sound absorption coefficient than particleboard, fibreboard and plywood for the frequency range of 500–8000 Hz [14]. Khedari et al. (2004) has developed particle composite boards from agricultural waste products using combinations of durian peel and coir fibre straw particles instead of wood as an insulation board in wooden construction industry [15]. Coconut coir fibre compressed into bales and mattress sheet was found to demonstrate good sound absorption coefficient. When compared to a single layer, multi-layer coconut coir fibres with airspace layers increase the absorption coefficient of the material at lower frequencies. Lee and Chen (2001) reported that the acoustic absorption of multi-layer materials is better with perforated plate backed with airspaces. Ersoy and Kucuk have investigated with three different layers of tea-leaf fiber waste materials with and without backing provided by a single layer of woven textile cloth were tested for their sound absorption properties.

Materials and Methods

Preparation of composites is divided into two stages, namely the preparation of Thermoset polymer matrix reinforced with kenaf natural fibre composites (Sample A1 and A2) and preparation of Thermoplastic polymer marix reinforced with kenaf natural fibre composites (Sample B1 and B2).The preparation of Sample A1 with fibre length of 1 mm and A2 fibre length of 0.6 mm as follows,The kenaf fibre, urea formaldehyde and hardener were weigh to the correct composition. First the urea formaldehyde was mix with the curing agent and water to completely dissolve the mixture. Then the mixture was transfer to a bottle to be used in a spray gun. The spray gun and a rotary drum mixer are used to ensure that the adhesive are evenly mixed with the kenaf fibre. The process will take about 15 to 20 minutes. After the mixing process, the mixture was transfer to a 30cm X 30 cm X 25 mm box mould made of wood. Then, the mixture was compress to shape the composite. The mould was then removed from its position. The composite was relocated into a hot press machine which was preheated to 180°C. The pressure of the machine is initially set to 550 Psi for 2 minutes. Then the pressure was gradually decreased to 300 Psi and 150 Psi for 2 minutes respectively. After the process, the hot press machine was release and the composite was cool down to room temperature. Preparation of Sample B1 with fibre length of 1 mm and B2 fibre length of 0.6 mm as follows, The Polypropylene,kenaf fibre and coupling agent were weigh to the required proportion. The polypropylene, kenaf fibre and coupling agent are mixed and loaded into the mould of size 30cm X 30cm X 25 mm. The hot press is pre-set at 1800C and at a pressure 1000 Psi, the mould is put under lower and upper Jaws of the hot press and loaded for 30 minutes. After 30 minutes the mould was cooled by using water as the coolant. The resultant boards were trimmed to avoid edge effects and then cut into specimen size using CNC cutting machine according to required size.

Results and Discussions

The measurements were based on a two-microphone transfer function method according to ASTM E1050-10, which is for horizontally mounted orientation-sensitive samples. Figure 12 shows the equipment used in the test and the test setup, this is home-made setup according to International standards [18]. The sample was placed at the end of the impedance tube and backed by a rigid surface.Figure 13 shows the variation of sound absorption coefficient against frequency for 4 different samples.It is evident that type of polymer influences the sound absorption coefficients. All the samples exhibited similar pattern of sound absorption at all frequencies. For all the samples, when the frequency increased, sound absorption coefficient also increased. Measured value shows not much significant differences between urea-formaldehyde and polypropylene in kenaf fibre reinforced composites on Sound absorption coefficient. The specimens made of kenaf fibre reinforced with polypropylene shows higher sound absorption coefficients compared with specimens made of Urea-formaldehyde. These polymers show the same reaction against sound waves over a wide frequency ranges. The sound absorption coefficients of the composites increased as the frequency increased. However, they decreased somewhat at a frequency of 1200 Hz and then increased again. This point of inflexion was due to the specific characteristic of kenaf fibre reflecting sound 1200 Hz, but absorbing sound in the low, middle and high frequency ranges.

Conclusions

In this investigation the sound absorption coefficients of natural fibre reinforced with two kinds of plastics have been tested. The results show that the samples made of Thermoplastics (Polypropylene) have high sound absorption coefficients compared with the samples made of Thermoset plastic (Urea-formaldehyde). Various size of the kenaf fibre showed unclear effects on sound absorption coefficients. In some frequency it increased but in other frequencies do not have significant effect. By introducing the composite materials from natural fibre reinforced polymeric materials, the resulting materials shows a good potential to be an environmentally friendly products. These new composites have a good future because they are cheaper, light weight and environmentally superior compare to glass fibre and mineral based synthetic fibre.

References:

Sound Absorption Composite Materials

Natural fibres are low-cost, lightweight and environmental friendly compared to glass fibre andmineral based synthetic materials. Moreover, natural fibres are sustainable, i.e. a resource produce for the needs of present without affecting the future needs.In addition, these natural materials are bio-degradable, nonabrasive, abundance and having less health and safety risk while handling and processing [9]. D’alessandro and Pispola [10] measure sound absorbing panels made of Kenaf and blankets of recycled polyester (PET) fibres. Both samples were tested in reverberation chamber, acoustic properties of both samples are good at frequency rangebetween 1000 Hz to 5000Hz with the average of 0.8. Yang et al. [11] utilized rice straw to become insulation boards to overcome lacking of solid woods in wood-industry. The rice straw was mixed with commercial binder to have certain shape and strength. The absorption coefficient is found to be on the average 0.5 between 1000 Hz to 8000 Hz. Sound absorption characteristic values of rock wool were measured and found to be similar to glass fibre [12].From the view of environmental protection, natural bamboo fibres were used for sound absorbing purposes. Impedance tube measurement of the bamboo fibre samples, reveal similar properties to that of glass wool. [13]. Composite boards of random cut rice straws and wood particles, were found to demonstrate higher sound absorption coefficient than particleboard, fibreboard and plywood for the frequency range of 500–8000 Hz [14]. Khedari et al. (2004) has developed particle composite boards from agricultural waste products using combinations of durian peel and coir fibre straw particles instead of wood as an insulation board in wooden construction industry [15]. Coconut coir fibre compressed into bales and mattress sheet was found to demonstrate good sound absorption coefficient. When compared to a single layer, multi-layer coconut coir fibres with airspace layers increase the absorption coefficient of the material at lower frequencies. Lee and Chen (2001) reported that the acoustic absorption of multi-layer materials is better with perforated plate backed with airspaces. Ersoy and Kucuk have investigated with three different layers of tea-leaf fiber waste materials with and without backing provided by a single layer of woven textile cloth were tested for their sound absorption properties.

Materials and Methods

Preparation of composites is divided into two stages, namely the preparation of Thermoset polymer matrix reinforced with kenaf natural fibre composites (Sample A1 and A2) and preparation of Thermoplastic polymer marix reinforced with kenaf natural fibre composites (Sample B1 and B2).The preparation of Sample A1 with fibre length of 1 mm and A2 fibre length of 0.6 mm as follows,The kenaf fibre, urea formaldehyde and hardener were weigh to the correct composition. First the urea formaldehyde was mix with the curing agent and water to completely dissolve the mixture. Then the mixture was transfer to a bottle to be used in a spray gun. The spray gun and a rotary drum mixer are used to ensure that the adhesive are evenly mixed with the kenaf fibre. The process will take about 15 to 20 minutes. After the mixing process, the mixture was transfer to a 30cm X 30 cm X 25 mm box mould made of wood. Then, the mixture was compress to shape the composite. The mould was then removed from its position. The composite was relocated into a hot press machine which was preheated to 180°C. The pressure of the machine is initially set to 550 Psi for 2 minutes. Then the pressure was gradually decreased to 300 Psi and 150 Psi for 2 minutes respectively. After the process, the hot press machine was release and the composite was cool down to room temperature. Preparation of Sample B1 with fibre length of 1 mm and B2 fibre length of 0.6 mm as follows, The Polypropylene,kenaf fibre and coupling agent were weigh to the required proportion. The polypropylene, kenaf fibre and coupling agent are mixed and loaded into the mould of size 30cm X 30cm X 25 mm. The hot press is pre-set at 1800C and at a pressure 1000 Psi, the mould is put under lower and upper Jaws of the hot press and loaded for 30 minutes. After 30 minutes the mould was cooled by using water as the coolant. The resultant boards were trimmed to avoid edge effects and then cut into specimen size using CNC cutting machine according to required size.

Results and Discussions

|

| Fig. 11. Diagram of the measurements set-ups (adapted from Handbook of Noise and Vibration) |

|

| Fig. 12 Experimental setup and sample specimens |

|

| Fig. 13 Comparison of Experimental results for sound absorption coefficients of samples |

Conclusions

In this investigation the sound absorption coefficients of natural fibre reinforced with two kinds of plastics have been tested. The results show that the samples made of Thermoplastics (Polypropylene) have high sound absorption coefficients compared with the samples made of Thermoset plastic (Urea-formaldehyde). Various size of the kenaf fibre showed unclear effects on sound absorption coefficients. In some frequency it increased but in other frequencies do not have significant effect. By introducing the composite materials from natural fibre reinforced polymeric materials, the resulting materials shows a good potential to be an environmentally friendly products. These new composites have a good future because they are cheaper, light weight and environmentally superior compare to glass fibre and mineral based synthetic fibre.

References:

- Yu, B.Z., New hot isolation and sound absorption damp material–porous polyme,. New Architect Mater, 3(4), 9–12, 1999.

- Zhang, J., Zhao, S.L., Guo, Y., et al., Repolypropylene block burn foam absorption sound on research, Noise Libration Control, 3, 36–39, 1997.

- Yang TL, Chiang DM, Chen R. Development of a novel porous laminated composite material for high sound absorption. J Vib Contr 2001;7(5):675–8.

- Murugan D, Varughese S, Swaminathan T. Recycled polyolefinbased plastic wastes for sound absorption. Polym Plast Technol Eng 2006;45(7):885–8.

- Kosuge K, Takayasu A, Hori T. Recyclable flame retardant nonwoven for sound absorption; RUBA_. J Mater Sci 2005;40(20): 5399–405.

- Hong Z, Bo L, Guangsu H, Jia H. A novel composite sound absorber with recycled rubber particles. J Sound Vib 2007;304:400–6.

- Hong Zhou BL, Huang G. A novel impedance matching material derived from polymer micro-particles. J Mater Sci 2007;42:199–206.

- F. Asdrubali 2007. Green and Sustainable Materials for Noise Control in Buildings, 19th International Congress On Acoustics.

- R. Zulkifli, Zulkarnain & MJ.M Nor 2010. Noise Control Using Coconut Coir Fiber Sound Absorber with Porous Layer Backing and Perforated Panel. American Journal of Applied Sciences. 7(2): 260-264.

- F. D’ Alessandro and G. Pispola 2005. Sound Absorption Properties of Sustainable Fibrous Materials in an Enhanced Reverberation Room. The 2005 Congress and Exposition on Noise Control Engineering.

- Yang HS, Kim DJ, Kim HJ. Rice straw–wood particle composite for sound absorbing wooden construction materials. Bioresour Technol 2003;86:117–21.

- Wang, C.N., Torng, J.H., Experimental study of the absorption characteristics of some porous fibrous materials. Applied Acoustics, 62, 447–459, 2001.

- Internet

No Responses to "Acoustic Absorption Performance of Natural Fibers and Their Composites"