A Presentation on Biocomposite Material

Ashish Kumar Dua

M.Tech, Dept. of Textile Engineering,

Indian Institute of Technology (IIT), Delhi.

Email: ashisdua@gmail.com

Cell: +91-9560480711

Ashish Kumar Dua

M.Tech, Dept. of Textile Engineering,

Indian Institute of Technology (IIT), Delhi.

Email: ashisdua@gmail.com

Cell: +91-9560480711

Biocomposites

Biocomposites or “Green” composites are fully degradable composites that are made up of biopolymer matrix and natural fibres as reinforcing phase.

Need of biocomposites

- To reduce depletion of petroleum reserves

- To reduce environmental pollution

- To utilise the agricultural waste

- To help attain sustainable development

- Reinforcing fibres are cheap and degradable

- Use of agricultural waste like bagasse, oil palm fibre, coir and rice husk etc.

- High amount of fibres/fillers reduces the quantity of matrix used.

- Fibres have disadvantages like aggregation and moisture absorption

- Composites thus made have poor interface and poor impact strength

- The cellulosic fibers have a cell arrangement, divert the crack path by blunting it.

- It hinders the dimensional stability as both matrix and fibres are hydrophillic

- Affinity toward water leads to delamination as the coupling agent no longer bonded to the fibre

- Voids

|

Fibres used in Biocomposite:

Eg. Brazil - sugarcane bagasse

Malaysia, Africa- Oil palm empty bunch fibre

Mid asia- hemp,sisal

Availability

Unique about fibres

- Jute

- Flax

- Ramie

- Hemp

- Kenaf

- Sisal

- Coir

- Oil palm fibre

- Bamboofiber

- Pineapple fibre

- Abaca/banana fibre

- Wood flour

- Sugarcane bagasse and rice husk

Eg. Brazil - sugarcane bagasse

Malaysia, Africa- Oil palm empty bunch fibre

Mid asia- hemp,sisal

|

|

Jute-

- Most widely studied lignocellulosic fibre

- Cheapest lignocellulosic fibre in our country

- Has high value of strength 400-800 MPa and modulus 30 Gpa

- Grown for fibres, it is not a waste

- Is not single cell fibre like cotton,so fibrillation can be used after removing bider lignin

- One of the fastest growing crop,mature in 8 months

- Has spiral angle of 2-10degree so very strong mechanical properties.

- Has inherent antimicrobial characteristics and easily available

- It is brittle so problem related to uniform processing

- It is reported to absorb UV radiation

- It is one of the large agricultural waste

- For 1 ton of oil,10 ton fibre waste is generated

- Large quantity is used as fuel or left open in environment

- Has inherent pores on its surface that helps in mechanical interlocking with matrix

- Drawback is the residual oil in the fibre

- There is large variation in diameter

- Has advantages of very high speed growth. It can grow upto 10cm per day. Mature in 3 months. Moreover it is cultivable in wide variety of weather.

- It suffers from severe agglomeration tendency due to hydrogen bond formation.

- Grown in Brazil and east asia only

- It is a hard leaf fibre

- Microfibril angle of 10-22° have a tensile strength of 530 MPa

|

| Sisal |

Abaca/Banana

Natural fibres allow moisture absorption from the environment which leads to poor bonding with the matrix materials. Chemical treatment modifies surface as well as chemistry of fibre in many cases.

Chemical treat performs 2 functions

Mechanism for natural fibres

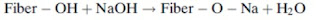

Alkylation or NaOH treatment

This involves treatment with Naoh at low conc. 1% to 18% with variable time (2-8 hours)

Only Kapok required high amount 400% for same result.

Reason is very highly packed crystalline structure of Kapok.

Some results are as follows….

Acetylation

Substitution of surface –OH group by stearic acid group or acetic group

In another method glacial acetic acid and acetic anhydride treatment is done subsequently with few drops of H2SO4.

Some results are as follows…….

# Acetylation will make the fibres non-polar and it becomes non reactive to polar resins like cashew nut shell liquid (CNSL)

# When tested on Flax fibre,the strength did not dropped significantly.

Other chemical techniques

Silane treatment is done to improve the hydrophillic nature of fibre. stages of hydrolysis, condensation and bond formation during the treatment.

By physical methods – internal chemical structure is intact, only surface topography is changed

Sugarcane bagasse is its residue after extraction. Presently used as

- Fibre is having a large lumen and are strong fibres.

- These are found to have good saline water resistivity.

- These are strongest among commercially available cellulosic fibres and its composites have better impact properties than flax and jute.

- It is a kind of waste

- Rice husk , coir and bagasse are the agricultural waste and are thus abundant.

Natural fibres allow moisture absorption from the environment which leads to poor bonding with the matrix materials. Chemical treatment modifies surface as well as chemistry of fibre in many cases.

Chemical treat performs 2 functions

- Removal of binding lignin to open up fibril bundle

- To make the fibre non polar by substituting its hydroxyl group. Thus the fibre is compatible with various hydrophobic resins

Mechanism for natural fibres

- Most natural fibres are lignocellolosic. Cellulose+lignin+hemicellulose (Hemicell.- D.P =200 Lignin- complex, crosslinked Polymers,binding material)

- Lignin binds the fibrils

- Removing lignin

- Exposes fibrils… Fibrillation

- Surface becomes rough

- Treatment should be peripherial only

|

This involves treatment with Naoh at low conc. 1% to 18% with variable time (2-8 hours)

- Fibres treated at high NaOH concentrations have reduced thermal resistance.

- X-ray studies reveal that order of the crystallite packing increase rather than an increase in the intrinsic crystallinity.

- Surface –OH bonds are modified as there is no peak at 1740 /cm shown in FTIR

- It reduces fibre diameter and uniforms it so that bonding and stress transfer improves.

|

Reason is very highly packed crystalline structure of Kapok.

Some results are as follows….

|

- At low NaOH conc the crystallinity improves but lowers at high conc.

- Cellulose structure changes (I to II)

- Experiments also done on 50% NaOH on coir and 5 % NaOH was used for removing residual oil from oil palm fibres.

Acetylation

Substitution of surface –OH group by stearic acid group or acetic group

Process- acetic acid and acetic anhydride individually does not react sufficiently with the fibres →

So fibres are initially soaked in acetic acid→ treated with acetic anhydride for 1-3 hours at elevated temp

In another method glacial acetic acid and acetic anhydride treatment is done subsequently with few drops of H2SO4.

Some results are as follows…….

|

# When tested on Flax fibre,the strength did not dropped significantly.

|

- Acetylation is milder treatment than NaOH treatment.

- The porosity of fibre is maintained during acetylation and diameter remains unaffected. Where as reverse in NaOH treatment

|

- Peroxide treatment

- Sodium chlorite treatment

- Isocyanate treatment

- Permanganate treatment

- Triazine treatment

- Oleoyl chloride treatment

- Fungal treatment

Silane treatment is done to improve the hydrophillic nature of fibre. stages of hydrolysis, condensation and bond formation during the treatment.

|

|

- Silane coupling agents act as a surface coating.

- This penetrates into the pores and develops mechanically interlocked coatings on fibre surface.

- Silane treated fibre composites provide better tensile strength properties than the alkali treated fibre composites

- Chemical link between the surface of the cellulose fibre and the resin through a siloxane bridge.

By physical methods – internal chemical structure is intact, only surface topography is changed

- Plasma treatment- role of gas used, pressure of air.

- Corona discharge- Surface itching for short time

- Stretching , calendring , thermo treatment

Sugarcane bagasse is its residue after extraction. Presently used as

- Fuel

- Paper industry

- Cellulose, 56%

- Hemicellulose 6%

- Lignin 29% (possibility of using as matrix?)

- Ash content 7%

- Organic extractive, 2%

|

Separated fibres are needle like,resembles glass fibre in appearence.

Reason of less research

Compared with other fibers, sugarcane fiber has a

Fibre separation

Adv- fibres are readily powedered and fibrillated

Alkali treatment

There are various ways reported.

Reason of less research

Compared with other fibers, sugarcane fiber has a

- Lower tensile strength

- Lower Young’s’ modulus,

- Higher moisture takeup

- But it has fast biodegradability

|

Adv- fibres are readily powedered and fibrillated

- Hammer milledà screened using meshà oven driedàrepeated water and alkali wash.

- Cut in piecesà washed in water at 70 Cà removal ofsoluble compoundsà transformed into pulp in blenderà washed with distilled water in sieve meshàagain washed at 70 c to removal small particles, medulla etcàdried until constant weightà organic solvents removed by soxhlet extractionà 48 hrs using cycle hexane and ethanol (1:1 by volume)

|

- The lignin content of sugar cane bagasse is high, 21% on the average

- It increases the resistance to chemical and microbial attack

- Reported to have very good compatibility with PLA without treatment

- Caro’s acid (persulfuric acid) treatment to remove lignin. 2 and 3 step process

- Benzoic acid was an effective adhesion promoter for BF/PVC composites

There are various ways reported.

- At room temperature using a mixture of glacial acetic acid, toluene, perchloric acid and anhydride acetic, for 48 h

- Mixture of acetic acid, anhydride acetic for 2 h up to 48 h.

- Higher temperatures were adopted using glacial acetic acid, sulfuric acid and anhydride acetic, at 35 C, followed by anhydride acetic addition at 18 C and 55 C for 5 h

- 1% NaOH treatment at 25 c for 1 hour is better than other conc.

- Readily attaches with PLA and polyhydroxylbutyrate (PHB), without modification.

- Flexural strength of PHB increased by 50% ,reinforcing the polymer with 30% v/v washed and acetone-treated bagasse fibers

- Poly[methylene (polyphenyl isocyanate)] (PMPPIC), succinic anhydride are successfuly used as coupling agents.

- Optimum mass fraction is 40% to 60% for good impact resiatance.

- Very few literature with biodegradable matrices

- It is one of the large agricultural waste

- For 1 ton of oil,10 ton fibre waste is generated

- Large quantity is used in making pottasium fertilizer or as fuel or left open in environment

- Has inherent pores on its surface that helps in mechanical interlocking with matrix

- There is large variation in diameter

- Drawback is the residual oil in the fibre.

|

India is a major Importer despite large production Agricultural ministry-North east and southern india

Morphology and properties-

Morphology and properties-

|

- It is hard and tough similar to coir fibers

- porous surface morphology (also facilitates penetration of water)

- The major constituents of these fibers were found to be cellulose. Lignin content is comparatively less

- Controversy over the fibrillar structure

- Starch and silica granules present. Silica can be removed mechanically to give clear pores.

- Cellulose 42.7–65%, lignin 13-20%, hemicell-17-33%

- Strength is comparable to coir

|

The pores became more prominent upon alkali treatment 5% NaOH for 48 hours, 25 c temperature

Experimental

|

Treatment | Effect |

Mercerization | Amorphous waxy cuticle layer leaches out |

Gamma irradiation | Partially eliminates the porous structure of the fiber and causes microlevel disintegration. It degrades mechanical properties. |

silane treatment | Imparts a coating on fiber surface |

Acetylation | Removes waxy layer from the surface and makes the fiber hydrophobic |

alkali treatment | makes the surface pores wider and fiber become thinner due to dissolution of natural and artificial impurities |

Oil extraction | bright colour to the fiber. Removal of oil layer exposes surface pits and makes surface coarse |

1. Silane treatment (1% silane solution (tri- ethoxy vinylsilane) in water–ethanol mixture (40 : 60) for 3 h. pH 3.5–4) gives better result than alkali treatment

2. Various coupling agents used for it

Abundant and used for oil and protein suppliment. As rich in protein, it has various functional groups besides amino and carboxyllic groups. It is also brittle in nature. Its major components, 11s and 7 s are reported to be capable of polymerisation

2. Various coupling agents used for it

- Epolene (maleic anhydride modified-polypropylene)

- Poly[methylene (polyphenyl isocyanate)] (PMPPIC)

- γ –methacryloxypropyltrimethoxysilane

- Vinyltri (2-methoxy ethoxy) silane

- γ –aminopropyltriethoxysilane

- Poly(propylene-acrylic acid)

- Poly (propylene-ethylene acrylic acid)

- Effect of OPF size on the composite properties

- Information on thermal properties, electrical resistance, high voltage break down characteristics,

- Degradation/weathering characteristics, deflection in thermal environment, rheology, resistance to various chemicals etc.

- OPF compatibility and mechanical properties with biodegradable matrices.

- Matrices from natural resources are mostly hydrophillic.

- Do not require Coupling agent to compatiblize the interface

- starch, Soy protein, PLA , lignin from wood waste etc.

- Disadvantage is their Brittle nature and low processing temperature

- Has high potential as matrix as it can be manufactured in large scale once the prodution technology successfuly invented.

- PLA is brittle (and its blend with startch is still brittle)

- PLLA m.p 170-183 C, Tg- 55-65 C density 1.25 g/cc PDLLA Tg 59 C. PLLA is crystalline in nature ,PDLLA is fully amprphous..

- Kenaf and PLA composites are widely studied.

- Decomoses by hydrolitic cleavage by ester group then chain breaks to smaller chain and monomers. Most chain ends are carboxylic that autocatalyse the hydrolysis step

Abundant and used for oil and protein suppliment. As rich in protein, it has various functional groups besides amino and carboxyllic groups. It is also brittle in nature. Its major components, 11s and 7 s are reported to be capable of polymerisation

- Soy flour- 50% protein

- SPC or soy protein composites – 60% protein + carbohydrates

- SPI or soy protein integrate - 90% protein and is refined form of SPC

- Soy milk

No Responses to "What is Biocomposite | Fibers Used in Biocomposites"